Structure and Manufacturing

Engineers design modern outdoor coolers to maintain low internal temperatures for long periods, even in demanding conditions. Many high-performance coolers use a rotational molding process that forms a seamless, one-piece body. During production, heat and rotation distribute material evenly along the mold, creating uniform wall thickness and smooth interior surfaces. This approach strengthens corners and eliminates weak points that could cause cracking or leaks.

A rotomolded body gives the cooler exceptional durability. Its consistent walls and integrated design protect the insulation core and prevent structural failure, even after repeated use in extreme temperatures or rough handling.

Insulation and Thermal Retention

Manufacturers improve insulation by injecting dense foam between the inner and outer shells. A tight-fitting lid seal prevents warm air from entering and cold air from escaping. This combination allows the cooler to preserve ice and perishable items for several days. The performance depends on wall thickness, gasket design, and how well the lid compresses when closed.

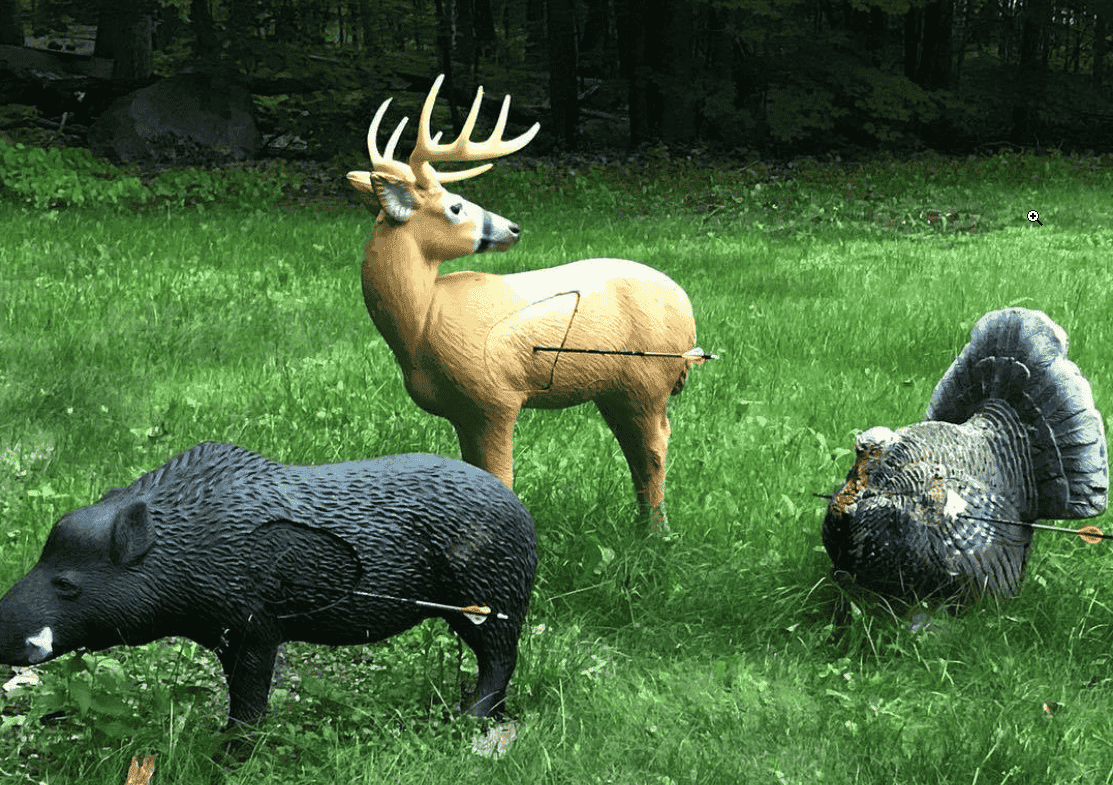

Reliable insulation makes rotomolded coolers suitable for long hunting trips, fishing expeditions, and extended backcountry travel. The balance between strength and thermal efficiency allows users to rely on them where conventional coolers might fail.

Durability and Field Application

Designers reinforce rotomolded coolers to withstand impact, pressure, and exposure. Molded handles, strong hinges, and secure latches keep the cooler intact during transport and field use. The rigid outer shell resists deformation, while the interior remains protected from heat and moisture.

Different sizes and layouts serve a range of purposes—from single-day outings to multi-day expeditions. Some designs include textured surfaces for grip, non-slip feet, and drain systems for easier cleaning. Color and surface choices help reflect heat and blend naturally with outdoor surroundings.

The Role of Design Innovation

Continuous innovation in cooler design shows how materials science and user experience shape outdoor equipment. Engineers test new polymers, insulation methods, and sealing systems to enhance performance without adding unnecessary weight. Each improvement strengthens durability, improves efficiency, and supports the needs of modern outdoor activity.

By combining careful engineering with practical testing, rotomolded coolers demonstrate how modern design supports both function and reliability. Their evolution highlights the connection between manufacturing innovation and dependable performance in the field.